Sponsored by DuPont.

The automotive business is quickly evolving, and electrical automobiles are on the forefront of this transformation. Continued EV adoption hinges on a number of key components: lowering prices, constructing a sturdy charging infrastructure, and designing environment friendly, sturdy battery packs with longer-range and fast-charging capabilities. As automakers try to match the price and effectivity of inner combustion engine automobiles, the race to develop high-performing EV battery packs is on—and adhesives are rising as a crucial element of their design and meeting.

Design Developments Shaping EV Battery Meeting

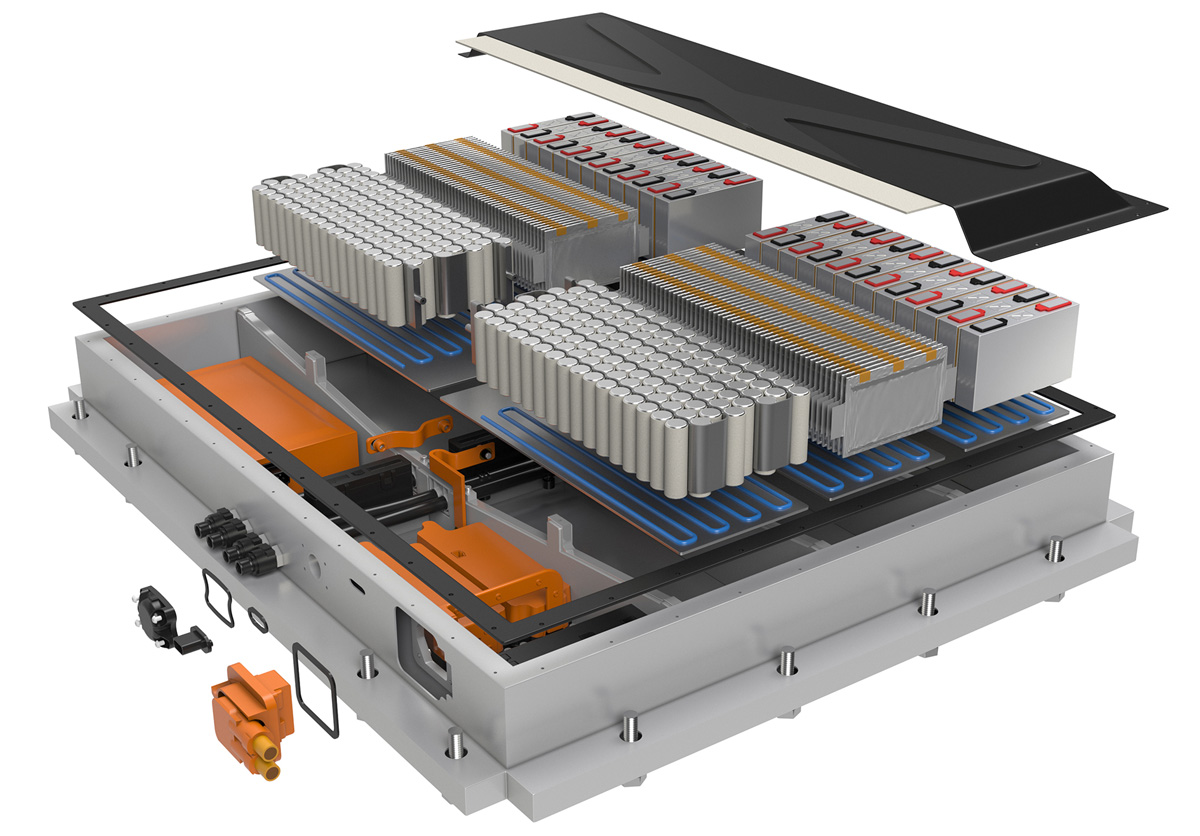

EV battery pack design is quickly evolving as automakers and researchers work to spice up efficiency, lower prices, and improve sustainability. The main target is on rising power density and decreasing value per kWh, resulting in easier designs that take away elements, weight, and bulk. Nonetheless, these modifications can have an effect on structural help and complicate battery alternative, disassembly, and recycling. Superior adhesive expertise may also help develop options for these challenges and usher EV battery pack designs into the longer term.

Right here’s a better take a look at the evolution of EV battery expertise:

- Cell-Module-Pack (CMP) designs bundle particular person cells collectively inside modules, a way that has dominated the market as a consequence of its sturdiness, ease of meeting, and serviceability. Since CMP requires extra elements that enhance value and weight, automakers now search designs with fewer elements to enhance power effectivity and simplify manufacturing.

- Cell-to-Pack (CTP) designs combine battery cells immediately into the battery pack, eliminating modules to reinforce power density and simplify manufacturing. This rising choice is gaining traction for its cost-lowering potential. Nonetheless, it calls for superior thermal administration and sturdiness, and a posh meeting course of leaves little room for error.

- Cell-to-Physique (CTB) designs incorporate the battery cells immediately into the automobile’s physique, optimizing house, lowering weight, and enhancing structural integrity. Early adopters are exploring CTB for its value effectivity and decreased half depend. Regardless of its benefits, considerations about sturdiness, recyclability, and security persist.

The Advantages of Adhesives in Sustainable Battery Meeting

As EV adoption grows, the necessity for sustainable, environment friendly battery meeting turns into extra urgent. Adhesives provide a spread of advantages that make them very important to EV battery manufacturing.

- Enhanced Efficiency—Adhesives improve battery efficiency by optimizing the thermal interface between battery cells and cooling methods, resulting in prolonged vary and sooner charging.

- Versatile Battery Design—Adhesives allow larger design flexibility by bonding quite a lot of supplies, together with composites, practical movies, and metals. This non-destructive becoming a member of approach preserves the integrity of substrates, permitting for progressive battery designs that have been beforehand unattainable.

- Elevated Power Administration for Security—Security is paramount in EV battery design, and adhesives contribute to crash power administration. They supply steady bond strains that improve structural integrity of the battery pack and allow wheel-to-wheel battery designs that carry out below crash situations.

- Added structural functionality – with the rising adoption of cell-to-body designs, adhesives can present the bonding energy vital to exchange modular partitions and help buildings

- Optimized thermal administration – Thermal administration is essential for battery security. Thermally conductive adhesives and interface supplies help warmth dissipation and stop overheating throughout battery charging and operation. Lengthy-term, this helps guarantee constant efficiency and prolong the battery lifespan.

- Assist for Zero-Emission EVs—Adhesives contribute to sustainability by enabling light-weight automobile designs and lowering panel thickness in physique buildings. This may end up in important CO2 financial savings—roughly 133 grams per pushed kilometer.

- Improved Manufacturing Processes—Adhesives streamline manufacturing processes, providing quick, low-cost becoming a member of and curing. They remove the necessity for floor pretreatment and might enhance course of pace, leading to important value financial savings.

Rising strategies in battery meeting additionally favor adhesives. Injectable adhesives are simply disbursed for modular battery frames. Debonding-on-demand options facilitate simple restore and recycling. Moreover, sure adhesives treatment on demand—splendid for versatile, lean manufacturing processes.

DuPont’s Options for Superior EV Battery Meeting

DuPont, with its deep experience in EV battery meeting, is well-positioned to help the business shift towards extra superior battery designs. Our big selection of adhesive options are designed to satisfy particular challenges, providing enhanced efficiency, security, and sustainability.

- BETAFORCE™ Elastic Structural Adhesive: A 2024 R&D 100 award winner, BETAFORCE™ is designed for broad EV battery meeting functions, excelling in pouch cell bonding. It bonds aluminum laminated movie substrates with out primers or pretreatment—delivering sturdiness, crashworthiness, and sustainability advantages. With as much as 30% renewable and bio-based supplies and room-temperature curing, it eliminates the necessity for high-temperature ovens, enhancing its environmental credentials.

- BETAMATE™ Structural Adhesive: BETAMATE™ ensures battery pack integrity with stiffness, sturdiness, and crash efficiency. It bonds and seals battery pack enclosures and cooling plates, providing robust adhesion to aluminum alloys and composites. It additionally can be utilized within the rising space of CTB designs. BETAMATE™ additionally improves security, corrosion resistance, and manufacturing effectivity.

- BETATECH™ TIM (Thermal Interface Materials): This progressive resolution is diisocyanate- and silicone-free and effectively manages and controls warmth from high-density batteries throughout charging and operation, sustaining thermal conductivity throughout a large temperature vary. BETATECH™ is simple to dispense and be part of, making it splendid for high-volume meeting.

Sustainability

Sustainability is on the core of DuPont’s mission. Our adhesive options are designed to deal with urgent challenges whereas enhancing EV efficiency and security.

- BETAMATE™ Broad Bake Adhesives: These adhesives enable for a discount in e-coat oven temperature by 25°C, resulting in important power financial savings. Additionally they allow shorter oven cycle occasions, additional enhancing manufacturing effectivity.

- BETAFORCE™ 2800 TC: This adhesive not solely retains EV batteries cool throughout quick charging to increase battery life, but additionally reduces uncooked supplies wanted by streamlining the variety of elements.

- BETATECH™ TIM: These adhesives provide a low pullout power to permit for straightforward removing of battery modules to allow restore, reuse, and recycling.

These product households are additionally accessible in room temperature treatment formulations. Oven-free bonding means much less power use and one much less step within the meeting course of.

Collaboration and Innovation: DuPont’s Facilities of Excellence

At DuPont, we imagine within the energy of collaboration. Our Facilities of Excellence and superior engineering capabilities across the globe are devoted to working intently with clients to drive innovation in EV battery meeting.

- Quick-Paced Growth: We now have the formulation and testing experience to validate new ideas and refine present ones.

- Complete testing: To confirm efficiency, longevity, and security of the deliberate configuration, we develop small pattern exams to module-scale testing on the battery system stage.

- World Collaboration: Our groups collaborate throughout areas, features, and companies to ship cutting-edge options tailor-made to the distinctive wants of our clients.

Able to Collaborate?

DuPont is greater than only a provider: we’re a accomplice in innovation. Should you’re seeking to advance your EV battery meeting course of, we invite you to dEVelop with DuPont to discover how our adhesive options may also help you obtain your targets.